„We will no longer structure the series based on length, size, and width, but rather on the status of the electrical system. In the future, the nature of the electrical system will be more important than the hardware, meaning the automobile itself.“

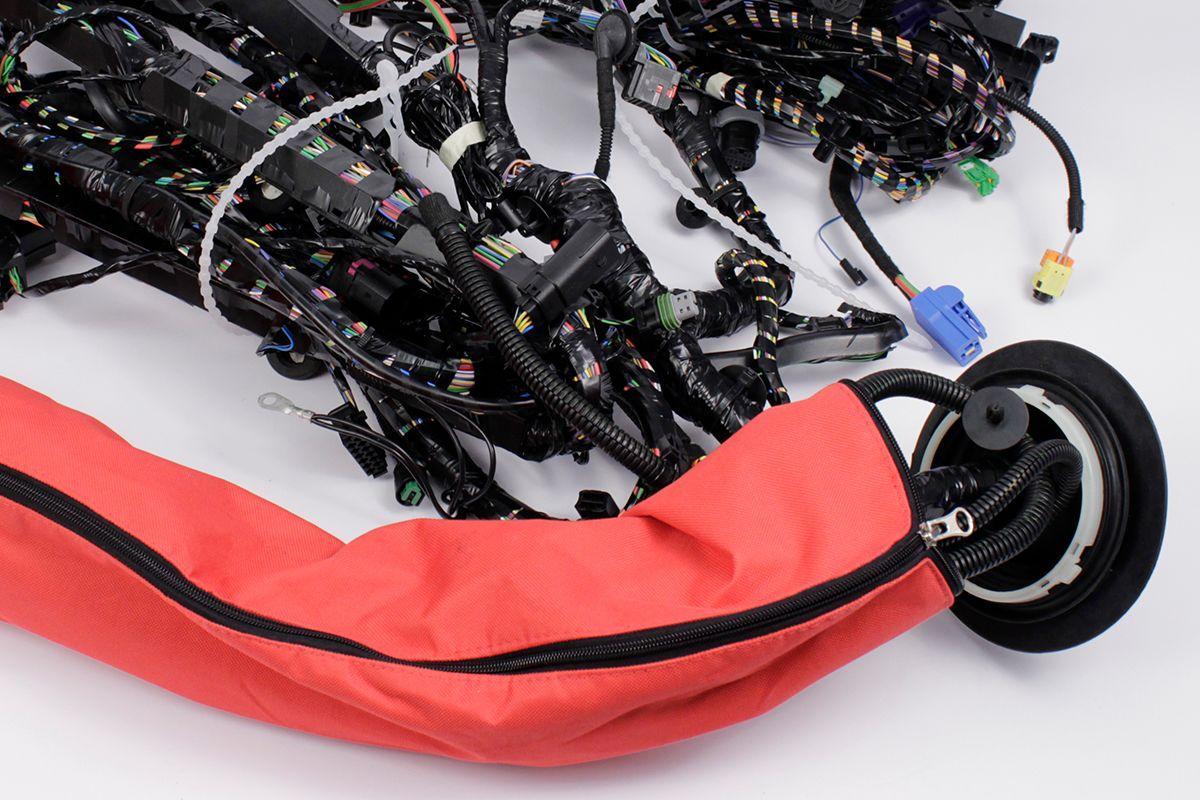

Harness Packaging: Durable, Tear-Resistant and Robust

Wiring systems serve as the nervous system of a vehicle, transmitting signals from sensors and control units throughout the car.

The assembly process demands meticulous care to prevent any damage. For decades, iba harness packaging has been a trusted solution for leading automotive manufacturers worldwide. Our threading aids, pouches, and wrapping cloths are designed to facilitate the efficient and secure installation of wiring systems. Fully custom-made, they support the handling of complex, arm-thick cable bundles—navigating corners and edges with ease.

Our harness packaging is engineered to be durable, tear-resistant, and robust, capable of withstanding rigorous use. This performance is achieved through the use of specialized threading aids, assembly bags, and structural bags. We incorporate abrasion-resistant and ESD-compliant* materials such as ESD-Tech and Multifil. Notably, Multifil withstands up to 750,000 Martindale abrasion cycles, ensuring exceptional longevity. Additionally, we utilize cotton, mesh, and proprietary material innovations to meet diverse application needs.

Ensuring optimal fit and protection in even the most challenging and hard-to-reach areas is our top priority. We collaborate closely with you to develop tailored harness packaging solutions that precisely meet your individual specifications.

*ESD: Electrostatic Discharge

The 3 steps to your cable harness encasement:

1. Your requirements:

Is quick and easy access to the contents a priority? Which bag contents should be particularly protected? Based on these factors, we tailor our recommendations regarding the harness model, interior layout, placement of exterior pockets, and more. What materials are most suitable? Should the surfaces be smooth and low-friction to facilitate handling on the assembly line, or is ESD-compliant material preferred to safeguard sensitive electronic components? We can also combine both, if needed. Finally, which closure options best fit your application?

Our team is ready to consult with you and design the ideal harness packaging solution that precisely meets your specifications.

The Practical Test:

No matter how advanced the testing methods, nothing replaces hands-on application in real-world conditions. That’s why we rely on full-scale, 1:1 prototypes—designed and handcrafted by our master fine bag maker in the IBA Hartmann prototyping department.

Each prototype is an exact replica of what will later be produced in series, allowing you to test the packaging under the actual challenges it will face throughout its lifecycle.

We dedicate the time needed to ensure every detail performs as intended. After testing, you decide which elements require refinement for series production.

Together, we develop your perfect harness packaging—proven in practice, tailored to your needs.

Production:

Based on your technical specifications, budget, timeline, and required quality certifications, your harness packaging is manufactured by one of our trusted production partners – located in Asia, Europe, or Germany

Your Advantages with iba hartmann TASCHEN

Custom Harness Encasement Solutions – Developed by Professionals

At IBA Hartmann, we design technically advanced packaging systems for wiring harnesses. With many years of experience, we provide carefully considered, practical solutions that simplify handling and installation.

You’re invited to see our expertise firsthand – either on-site or during a visit to our in-house prototyping workshop. In a personal consultation with our master fine bag maker in Augsburg, we’ll guide you through every detail of your tailor-made solution.

DIN ISO 9001:2015 certified.

As one of the first companies in our industry, we have been certified according to DIN ISO 9001 since 1996. This certification ensures that all project stages are managed in an organized, transparent, and standardized manner. Our Quality Management Officer (QMB) continuously monitors compliance with ISO requirements, guaranteeing consistently high quality—both during in-house product development and throughout production at our partner facilities.You can rely on consistent, high-quality results throughout your entire series production. Upon request, we can also document additional quality criteria through QMB inspections directly at our manufacturing sites.

Cable Harness Encasement – Always Custom-Made

At iba hartmann, every wiring harness packaging solution is individually tailored. Reorders are especially valuable to us—not only as a sign of your continued trust, but also as an opportunity for collaboration and improvement.

Each reissue opens the door to direct, in-depth dialogue. Your feedback from real-world use is important to us. It helps us identify areas for refinement—whether it’s optimizing the placement of exterior pockets, improving closure systems, or reinforcing highly exposed sections.

We don’t just replicate previous solutions—we build on them. You can rely on us to continuously evolve and enhance your harness packaging, ensuring it performs even better the next time around.

We don’t settle. We keep improving.